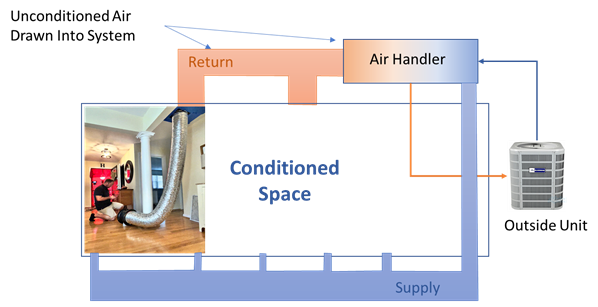

A basic duct leakage testing system includes three components: a calibrated fan, a register sealing system, and a device to measure fan flow and building pressure. Supply registers or return air grills are sealed using adhesive tapes, cardboard, or non-adhesive reusable seals. One register or return is left unsealed, and the calibrated fan is connected to it. Pressure is monitored in one of the branches of the ductwork while the calibrated fan delivers air into the system. As air is delivered into the ductwork, pressure builds and forces air out of all of the openings in the various ductwork connections or through the seams and joints of the furnace or air-conditioner. The tighter the ductwork system (e.g. fewer holes), the less air is needed from the fan to create a change in the ductwork pressure.

A duct leakage test can be performed by either pressurizing or depressurizing the ductwork. Ductwork that is outside the building envelope, such as in an unconditioned attic or crawlspace, should be pressurized so as to not bring in unwanted contaminants such as dust.